Just How Membrane Layer Bioreactors Are Transforming Water Filtration Equipments

The appearance of membrane layer bioreactors (MBRs) represents a considerable advancement in the area of water filtration, merging biological treatment procedures with innovative membrane filtering modern technologies. As global water shortage escalates, the duty of MBRs in helping with safe and clean water reuse and sustainable water monitoring becomes increasingly important.

Overview of Membrane Layer Bioreactors

Membrane bioreactors (MBRs) stand for a significant improvement in water purification technology, as they combine biological treatment procedures with membrane layer purification. This assimilation boosts the effectiveness of wastewater treatment by using bacteria to break down natural contaminants while at the same time employing semi-permeable membrane layers to different treated water from suspended virus and solids.

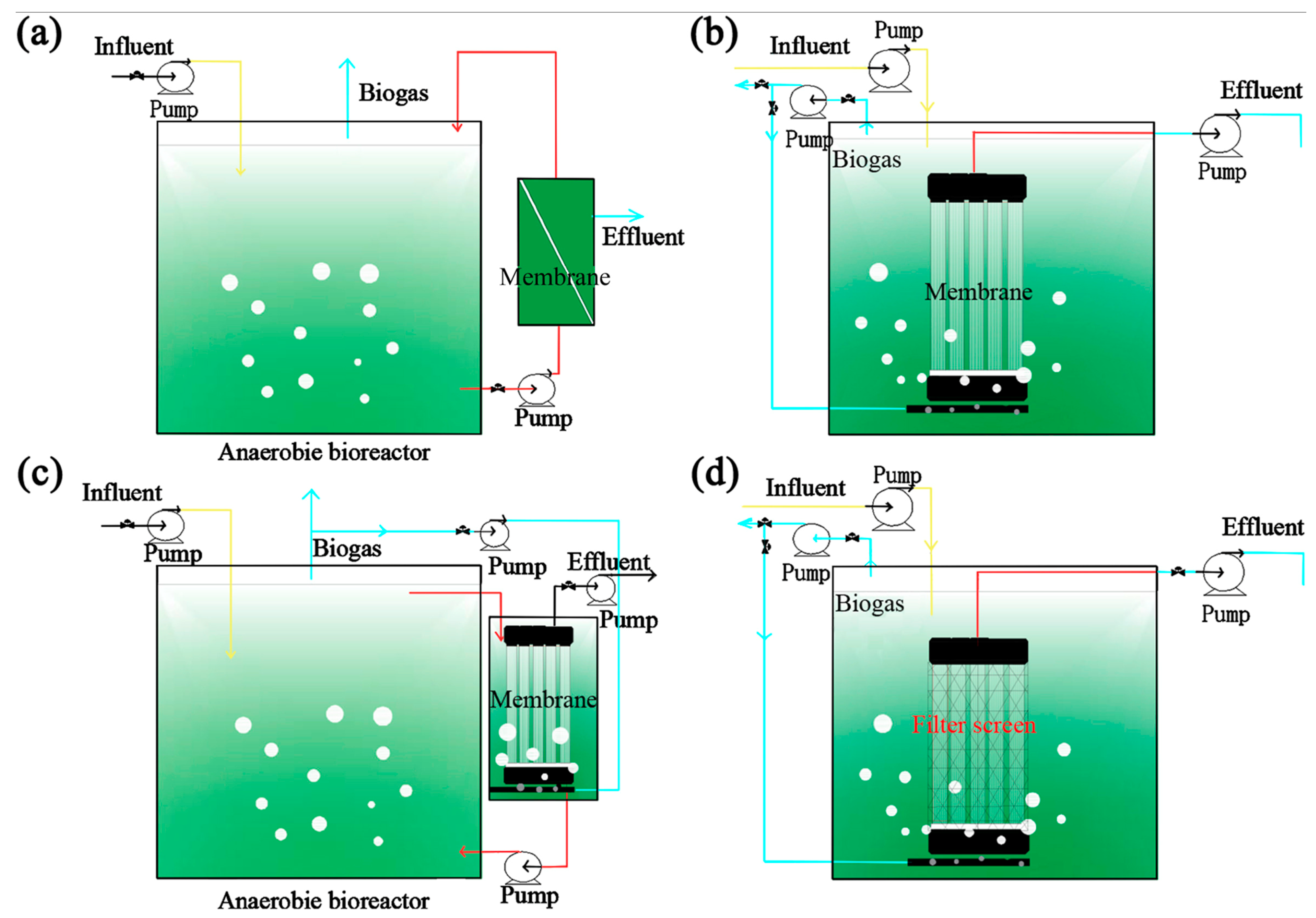

The MBR system generally consists of a biological activator where the microbial population metabolizes pollutants, followed by a membrane purification system that retains biomass and permits just clean water to pass through. This double performance causes higher effluent top quality contrasted to traditional therapy approaches. MBRs can be run in both set and continuous circulation settings, using flexibility in layout and application.

Additionally, MBRs are characterized by their small impact, making them ideal for urban setups with room constraints. Membrane Bioreactor. They additionally make it possible for the healing of water for reuse, thus adding to water sustainability campaigns. While MBR modern technology has obtained appeal in commercial and community applications, its operational intricacies and power needs necessitate cautious factor to consider during execution. Generally, MBRs go to the leading edge of enhancing water treatment performance and high quality, showcasing the possibility for cutting-edge options in environmental monitoring.

Advantages of MBR Innovation

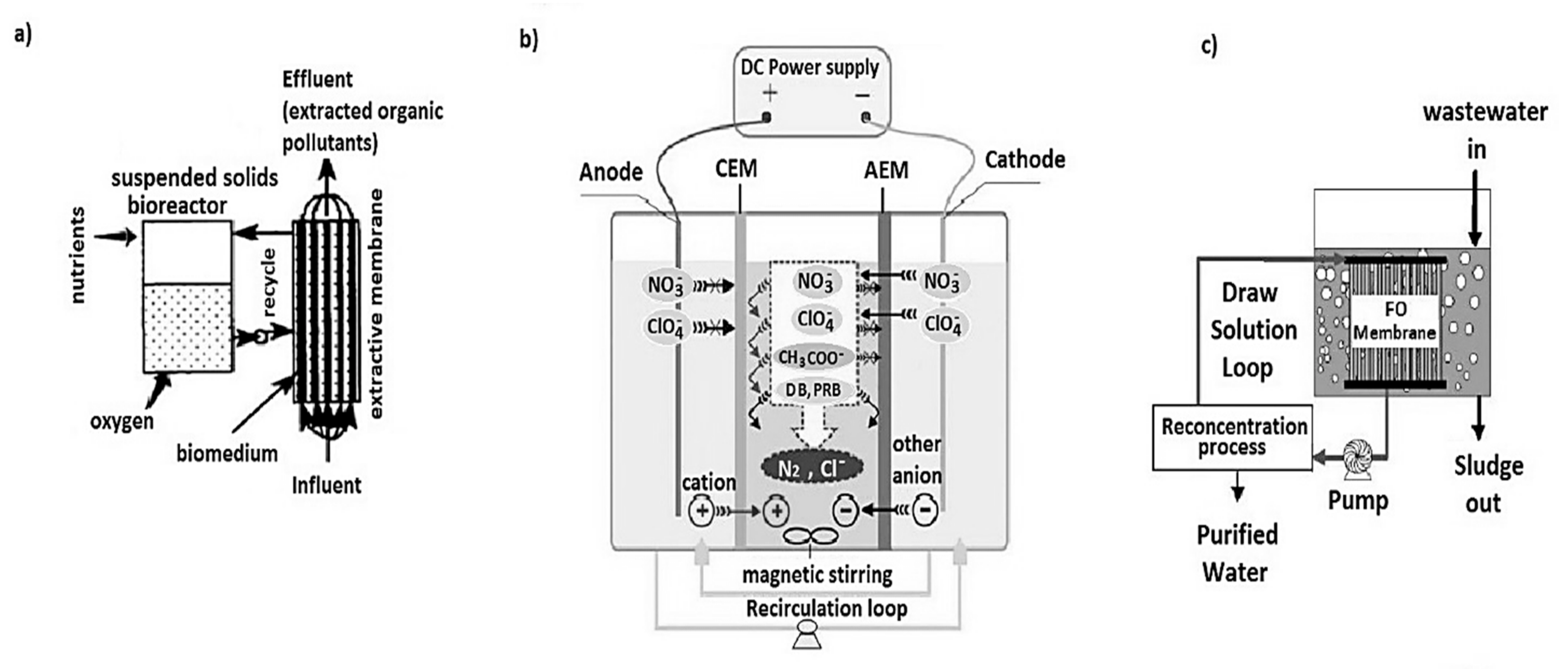

The assimilation of biological treatment with membrane filtration uses various advantages for water purification procedures. Among the primary benefits of Membrane layer Bioreactor (MBR) innovation is its capability to successfully eliminate both not natural and natural contaminants, bring about top quality effluent. The membranes work as a physical barrier, preventing put on hold solids and microorganisms from passing through, which boosts the general safety and security and reliability of treated water.

Furthermore, MBR systems call for a smaller sized impact compared to conventional treatment techniques, enabling a lot more reliable area usage. This compact design is specifically advantageous in city setups where land is restricted. MBRs likewise demonstrate functional versatility, suiting differing influent high qualities and circulation rates without substantial performance deterioration.

In addition, the process offers enhanced nutrient removal abilities, particularly for nitrogen and phosphorus, which are important for avoiding eutrophication in receiving waters. The decreased sludge production connected with MBR modern technology additionally translates to lower disposal costs, making it an economical remedy in the long run - Membrane Bioreactor. In general, the benefits of MBR modern technology position it as a leading choice for lasting and innovative water purification systems, dealing with both environmental and economic issues

Applications in Water Filtration

Applications of Membrane Bioreactor (MBR) technology in water filtration are impactful and varied, addressing numerous therapy needs throughout several industries. MBRs efficiently combine biological treatment procedures with membrane purification, making them suitable for metropolitan wastewater treatment, industrial effluent monitoring, and also potable water reuse initiatives.

In local settings, MBRs are significantly employed to enhance the quality of treated wastewater, permitting compliance with stringent discharge policies and helping with the recycling of water for watering and non-potable uses. Their small style additionally makes them appropriate for city atmospheres where area is limited.

Industrially, MBR innovation is used to treat process water and wastewater, specifically in sectors such as food and drink, drugs, and textiles. By effectively eliminating impurities and suspended solids, MBRs aid markets reduce ecological influences while recouping valuable resources from wastewater streams.

Additionally, MBRs are obtaining grip in decentralized water therapy applications, where small-scale systems can be released in remote locations or developing regions. This adaptability makes it possible for areas to achieve sustainable water monitoring options, improving access to clean water while lowering dependence on conventional therapy approaches.

Case Studies and Success Stories

In one more instance, a textile click site production facility in Bangladesh adopted MBR innovation to address its wastewater obstacles. The system reduced chemical oxygen need (COD) levels from 1,200 mg/L to less than 100 mg/L, hence meeting governing requirements and significantly decreasing ecological influence.

The University of Cape Town's MBR installment has actually shown efficient in dealing with greywater for non-potable reuse on school. This project not only saves safe and go to these guys clean water but also acts as an academic model for lasting methods.

In addition, a seafood processing plant in Norway used MBR modern technology to treat effluents including high degrees of raw material, attaining over 90% contaminant elimination. These study emphasize MBR technology's convenience and its essential role in boosting water high quality throughout diverse applications.

Future of Water Treatment Solutions

As worldwide water scarcity and air pollution difficulties magnify, innovative water treatment remedies are coming to be increasingly necessary to guarantee sustainable access to clean water. The future of water therapy hinges on the integration of sophisticated modern technologies that enhance the effectiveness and performance of purification procedures. Membrane layer bioreactors (MBRs) are at the center of this development, combining organic treatment with membrane layer filtering to generate top quality effluent appropriate for different applications.

Emerging trends such as resource recuperation from wastewater, consisting of nutrients and power, will even more change therapy facilities right into eco-friendly hubs. Moreover, developments in nanotechnology and membrane layer materials promise boosted efficiency and long life of filtering systems.

Verdict

Their duty in drinkable water reuse and sustainable water monitoring highlights their value in attending to international water scarcity challenges. Continued study and advancement will certainly additionally boost the efficiency and adoption of MBR technology, making certain a resilient future for water treatment services.

The appearance of membrane layer bioreactors (MBRs) represents a significant advancement in the field of water purification, merging organic treatment processes with sophisticated membrane layer filtering modern technologies. As worldwide water shortage intensifies, the duty of MBRs in helping with potable water reuse and lasting water monitoring ends up being significantly crucial. They likewise make it possible for the recovery of water for reuse, therefore adding to water sustainability initiatives.As worldwide water shortage and air pollution obstacles escalate, ingenious water therapy solutions are ending up being progressively crucial to make certain lasting access to clean water. Their role in drinkable water reuse and sustainable water management highlights their value in dealing with global water scarcity challenges.